I. The Core Position and Mechanism of Action of Water-Reducing Agents In concrete engineering technology, water-reducing agents are hailed as the "magic potion" for improving concrete performance. Their core value lies in:

1) Performance Optimization: Achieving a dual effect of reducing cement usage by 10%-15% and water usage by 15%-20% without altering concrete strength and slump.

2) Cost-Effectiveness: Directly reducing material costs while simultaneously increasing the 28-day strength of concrete by 20%-30%.

3) Current Status of Technology Popularization: Industry surveys show that approximately 80% of engineering technicians lack sufficient understanding of its mechanism of action.

4) Working Principle:

1. Water-reducing agents, through the characteristics of anionic surfactants, function as "dispersion artists":

2. Adsorbing onto the surface of cement particles to form a double electrical layer.

3. Generating electrostatic repulsion to break up particle agglomeration.

4. Achieving uniform dispersion of cement particles.

5. Releasing encapsulated free water, increasing fluidity by 30%-50%.

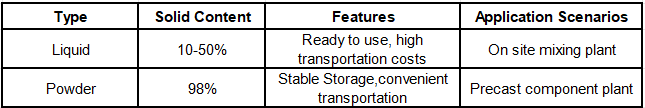

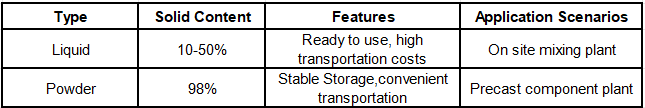

II. A Multidimensional Classification System of Water-Reducing Agents 1). Classification by Physical Form

2). Classification by Performance Grade:

Ordinary water-reducing agent: Water reduction rate 8%-12%, suitable for concrete below C30;

High-efficiency water-reducing agent: Water reduction rate 15%-25%, meeting the requirements of pumping construction;

High-performance water-reducing agent: Water reduction rate ≥30%, used for super high-rise buildings;

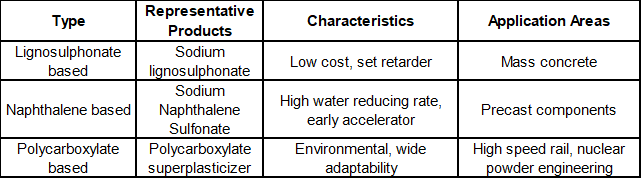

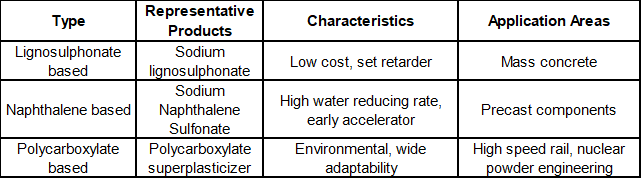

3). Classification by Chemical Composition

III. Five Core Functions of Water-Reducing Agents 1) Improved Economy: Saves 30-50 kg of cement per cubic meter of concrete, reducing material costs by 15%-20%;

2) Enhanced Strength: Reduces water-cement ratio by 0.05-0.10, increasing 28-day strength by 20%-30%;

3) Optimized Construction:

1. Slump retention time extended by 2-3 hours

2. Pumping pressure reduced by 30%-40%

3. Formwork filling efficiency increased by 50%

4) Improved Durability:

Imperibility grade increased by 2 levels

Carbonation depth reduced by 40%-60%

Chloride ion diffusion coefficient reduced by 30%-50%

5) Crack Control: Shrinkage rate reduced by 20%-30%, 28-day shrinkage value <0.03%

IV. Adaptation Solutions for Special Cement 1) High-alkali cement (alkali content ≥ 0.6%)

Problem: Rapid loss of fluidity, slump loss over 1 hour > 50mm

Solution:

Use a high-sulfate type water-reducing agent (SO₃ content ≥ 15%)

Add a retarding component (sodium gluconate dosage 0.03%-0.05%)

Control initial setting time to 6-8 hours

2. Low-alkali, sulfur-deficient cement (alkali content < 0.4%)

Problem essence: Insufficient soluble alkali leads to decreased dispersion efficiency of the water-reducing agent

Technical measures:

Supplement with 0.1%-0.2% Na₂SO₄

Use a low-air-entraining type water-reducing agent (air content < 2%)

Optimize fly ash content (controlled at 20%-30%)

3. High-blended cement (admixture content > 30%)

Performance impact:

When fly ash water demand ratio > 105%, fluidity decreases by 20%-30%.

When slag activity index < 75%, strength development is delayed.

Improvement solutions:

Increase water-reducing agent content by 10%-15%.

Add 0.01%-0.02% air-entraining agent to improve workability.

Use composite activator (gypsum + NaOH composite admixture, 0.5%-1.0%).

4). High C3A Cement (C3A content > 8%)

Mechanism of Action: C3A adsorbs 2-3 times more water-reducing agents than C3S.

Key Control Points:

Select high-sulfate type water-reducing agents (SO₃/C3A ≥ 1.5)

Adjust gypsum content to 5%-7%

Control hydration temperature rise < 25℃ (for mass concrete)

Conclusion: Innovation in water-reducing agent technology is driving concrete engineering towards high performance and green manufacturing. According to the China Concrete Association, by 2025, the market share of polycarboxylate-based water-reducing agents will exceed 85%, with a compound annual growth rate of 12%. Mastering the compatibility technology between water-reducing agents and cement has become an essential core competency for modern engineering technicians.