Refractory castables serve as the core material for high-temperature industrial furnaces. By precisely blending cementitious binders such as aluminates and silicates with aggregates, they achieve high-temperature resistance between 1300-1800°C. Combining ease of construction with corrosion resistance, they are widely used in critical areas of metallurgical plants and cement kilns.

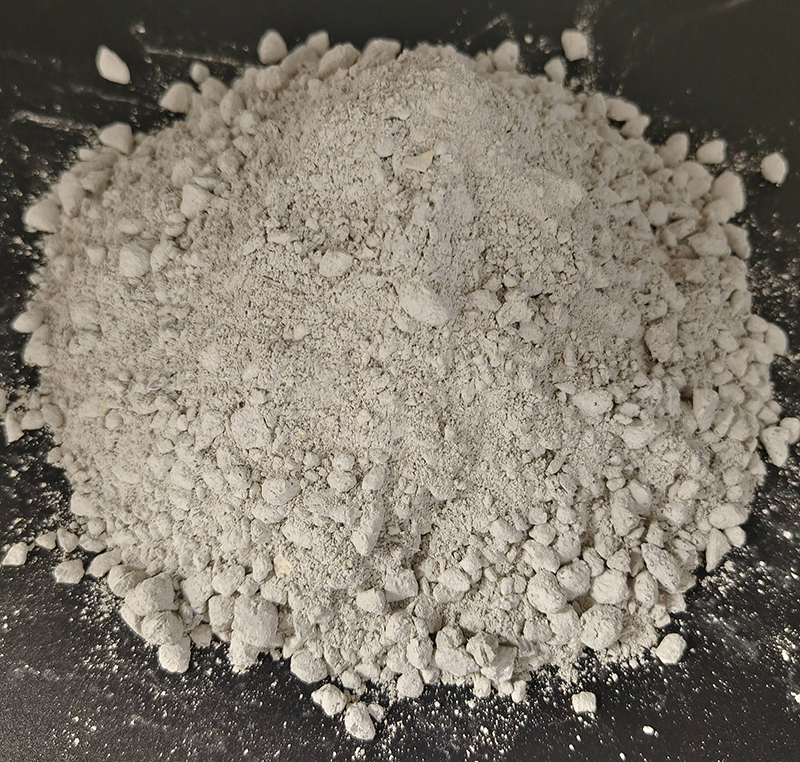

Refractory castables are mixtures composed of refractory aggregates, powders, and binders. When mixed with water or other liquids, they are suitable for construction via pouring or vibration methods. They can also be pre-fabricated into components with specified shapes and dimensions for constructing industrial furnace linings. To enhance the physical, chemical, and construction properties of refractory castables, appropriate additives are often incorporated, such as plasticizers, dispersants, accelerators, retarders, expansive agents, and gel-breaking agents. Furthermore, adding stainless steel fibers to castables intended for areas subject to significant mechanical stress or thermal shock can markedly increase the material's toughness. In insulating refractory castables, incorporating inorganic fibers not only enhances toughness but also improves thermal insulation properties. Due to similarities in basic material composition (aggregates, powders, admixtures, binders, and additives), setting and hardening processes, and construction methods with concrete used in civil engineering, refractory castables were historically termed refractory concrete.

Refractory castables feature a simple production process that saves labor and energy, offers high construction efficiency and quality, and allows for on-site mixing or selection of high-performance materials as needed. Consequently, they represent a widely used and versatile type of unshaped refractory material in furnace construction projects.

Adding polycarboxylic acid superplasticizers to refractory castables offers multiple benefits. First, due to the high density and poor flowability of refractory materials, casting presents significant challenges. Polycarboxylic acid superplasticizers enhance the flowability of refractory concrete, thereby reducing resistance and blockages during construction and improving work efficiency. Secondly, using polycarboxylic acid superplasticizers reduces water consumption and lowers the water-cement ratio, enabling more complete cement hydration and thus improving concrete performance. Finally, these superplasticizers mitigate temperature increases during concrete placement, reducing energy consumption for material sintering and further lowering costs.

In summary, polycarboxylic acid superplasticizers can be incorporated into refractory castables. Their addition effectively boosts construction efficiency, reduces costs, and improves material properties. However, practical application requires adjustments and optimization based on specific conditions to achieve optimal results.