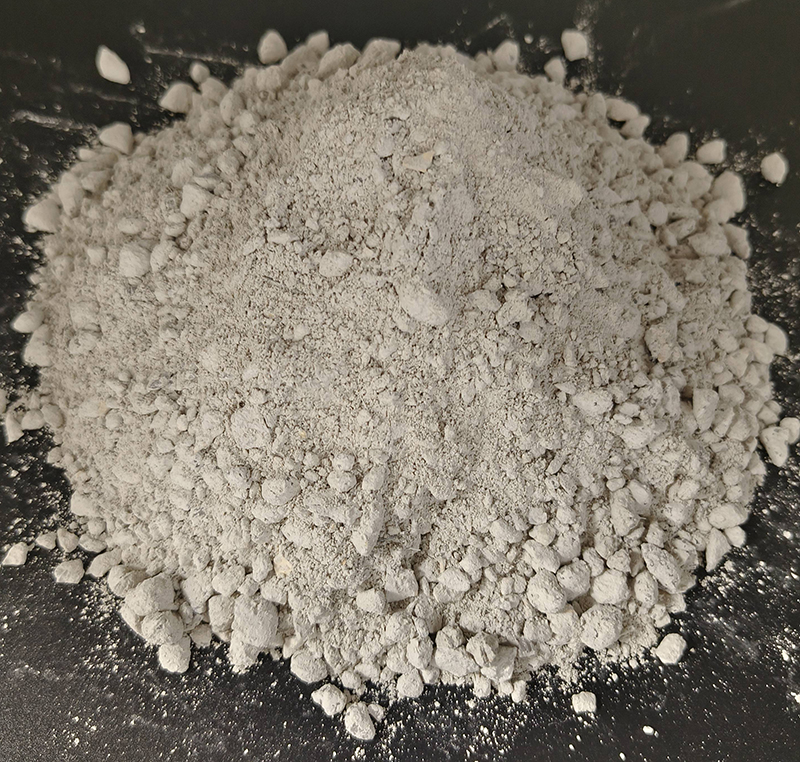

Refractory castables are mixtures composed of refractory aggregates, powders, and binders. After adding water or other liquids, they are suitable for construction using pouring or vibration methods. They can also be pre-made into prefabricated components of specified shapes and dimensions for lining industrial furnaces. To improve the physical and chemical properties and construction performance of refractory castables, appropriate additives are often added, such as plasticizers, dispersants, accelerators, retarders, expansion agents, and deflocculants. Additionally, for refractory castables used in areas subjected to significant mechanical forces or intense thermal shock, adding an appropriate amount of stainless steel fibers can significantly increase the material's toughness. In insulating refractory castables, adding inorganic fibers not only enhances toughness but also improves their insulating properties. Due to the similarity in basic material composition (such as aggregates and powders, admixtures, binders, and additives), hardening process, and construction methods between refractory castables and concrete in civil engineering, they were once referred to as refractory concrete.

The production process of refractory castables is simple, labor-saving, and energy-efficient, with high construction efficiency and quality. They can be prepared on-site or selected from high-performance materials as needed. Therefore, refractory castables are a widely used and versatile type of monolithic refractory material in furnace construction.

As a key material for high-temperature industrial kilns, the performance of refractory castables is closely related to the type of binder. Cement binders, with their excellent construction performance and wide applicability, serve as an important classification basis for refractory castables. In different refractory castable systems, material proportions also vary and require precise calculation and adjustment based on specific usage environments and requirements. Below are some common proportioning principles and methods for refractory castables:

(1) Calcium aluminate cement-bonded refractory castables

Calcium aluminate cement-bonded refractory castables are primarily composed of calcium aluminate minerals. Based on alumina content, they can be classified into ordinary calcium aluminate cement (CA-50, CA-60) and pure calcium aluminate cement (CA-70, CA-80). Their characteristics include high early strength and a refractory temperature range of 1300-1800°C, making them widely used in metallurgical furnace linings. Among them, ordinary calcium aluminate cement-bonded castables have high early strength and convenient construction, making them suitable for medium-high-temperature environments (1300-1500°C) such as metallurgical furnaces. Pure calcium aluminate cement-bonded castables, due to their higher alumina content, can achieve a refractory temperature of 1650-1800°C and are widely used in high-temperature key areas of cement rotary kilns, demonstrating excellent high-temperature stability and erosion resistance.

(2) Portland cement-bonded refractory castables

Portland cement-bonded refractory castables use ordinary Portland cement as the binder. Their temperature resistance is relatively low (<1000°C), but they are cost-effective and easy to construct. These castables are mainly used in non-high-temperature areas such as chimneys and low-temperature kilns, suitable for industrial environments with low requirements for refractoriness. Portland cement-bonded castables can maintain good mechanical strength and stability at low temperatures, making them a representative of economical refractory materials.

(3) Blast furnace slag cement-bonded refractory castables

Blast furnace slag cement-bonded refractory castables use blast furnace slag Portland cement as the binder. Their heat resistance is good (300-400°C), but their refractoriness is relatively low. These castables are mainly used in medium-low-temperature environments, such as insulation layers or auxiliary structures of some industrial furnaces. Blast furnace slag cement-bonded castables can maintain certain mechanical strength while also having good heat resistance and cost-effectiveness, making them an preferred option for medium-low-temperature applications.

(4) Low-calcium aluminate cement-bonded refractory castables

Low-calcium aluminate cement-bonded refractory castables significantly improve high-temperature performance by reducing calcium oxide content (CaO < 10%). These castables not only have excellent refractoriness (up to 1650°C or higher) but also demonstrate outstanding thermal shock resistance and erosion resistance, making them suitable for complex working conditions in industrial kilns. Low-calcium aluminate cement-bonded castables can maintain structural integrity at high temperatures, making them an ideal lining material for high-temperature areas.

(5) Heat-resistant cement-bonded refractory castables

Heat-resistant cement-bonded refractory castables are monolithic refractory materials made primarily with calcium aluminate cement (such as high-alumina cement or low-calcium aluminate cement) as the binder, mixed with refractory aggregates, powders, and additives. They are mainly used for lining high-temperature equipment such as cement rotary kilns, heating furnaces, and boilers in industrial kilns.