Setting Accelerator are admixtures shorten concrete set time and quick harden development.

Accelerating admixtures can be powder or Liquid, or can be divided into alkali, low alkali and no alkali according to the alkali content, It is used in shotcrete, mainly apply for the initial support and final lining of railway engineering, including urban underground railway engineering, highway construction, slopes of hydraulic culverts, slope engineering, repairing and reinforcing of factory chimneys and other industrial buildings, plugging and rescue, and new type of thin-sheeted construction.

The properties of mortar mixed with Set Accelerator should be complied with below table:

| Item | Norm |

| No Alkali Set accelerator | Alkali Set accelerator |

| slurry set time | Initial setting time(min) | 《 5 |

| final setting time (min) | 《 12 |

| mortar strength | 1d compressive strength(MPa) | 》7.0 |

| 28d Compressive strength ratio(%) | 》90 | 》70 |

| 90d strength retention rate(%) | 》100 | 》70 |

Note that the following conditions shall be consistent when conducting the comparison test: ①The variety and freshness of cement. ② adding way of quick-setting admixture and water ③Mixing method; ④Air and water temperatures Common components in accelerating agent:

Aluminium hydroxide AI(OH)2: or Al2O3-3H,O Sodium Aluminate NaAIO2 Sodium hydroxide NaOH Sodium carbonate Na2CO3. Potassium carbonate K2CO3. Aluminium sulphate Al2(SO4)3: 18H2O Sodium silicate Na2O-nSiO2-xH₂O Ammonium diethanol HN[CH2CH2OH]2 Ammonium triethanol (HOCH2CH2)3N Lime CaO Calcium chloride complex Glycerol [(1,2,3-)propanetriol] Methacrylic acid CH2-C(CH3)COOH Oxalic acid HOOCCOOH Propionic acid CH3CH2COOH Acetic acid (acetic acid) CH3COOH Lactic acid (2-hydroxypropionic acid) CH3CHOH-COOH Citric acid (HO)C(CH2COOH)2COOH Fly ash

Main varieties:

Sodium aluminates powder accelerator Compound sulphoaluminate type accelerator Sodium silicate plugging acceleratort Liquid sodium aluminates type accelerator Aluminium sulphate no alkali liquid accelerator Hydroxy aluminium no alkali liquid accelerator By the water reducer, sodium aluminate, sodium hydroxide, triethanol ammonium and little of polyacryloyl ammonium compounded into a solution accelerator has great effect on quick-setting, but the liquid storage time can not be too long, please contact Huaxuan company whhuaxuan.com for further specific specifications.

Guidance on application of Setting accelerator:

(1) must pay attention to the adaptability of cement when adding quick-setting agent, (2) Note that the dosage of agent must be appropriate. (3) Note that the water-binder ratio is not too large. the water-cement ratio should be controlled 0.4 ~ 0.6 (4) shorten storage time of the dry mixture , don't over 2h if no accelerator added, when mixture hybrid with accelerator, the storage time should not exceed 20min. (5)The agent should be mixed evenly. (6) select the appropriate type of quick setting agent For different engineering requirements (8) should pay attention to concrete wet maintenance to prevent dry cracking. After 2h of final setting, water should be sprayed for maintenance. (9) Different types of liquid agent cannot be compounded, and the spraying machinery should be fully cleaned when replacing the other one. (10)Alkaline agent is toxic and corrosive to human skin and eyes. Attention should be paid to labour protection and personal safety on construction site.

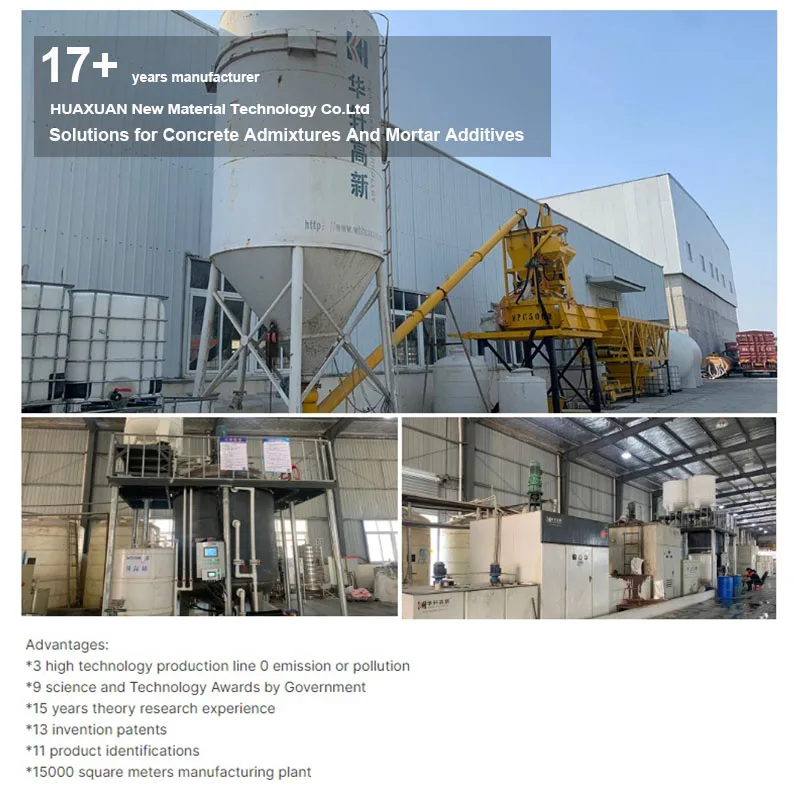

Wuhan Huaxuan Technology Co., Ltd. is a 16-year-old original construction concrete and mortar admixture manufacturer, our products are specially formulated to work with a variety of cementitious materials to achieve a full range of water reduction effects, thus achieving product versatility. We welcome partners interested in the development of chemical and mineral admixtures.