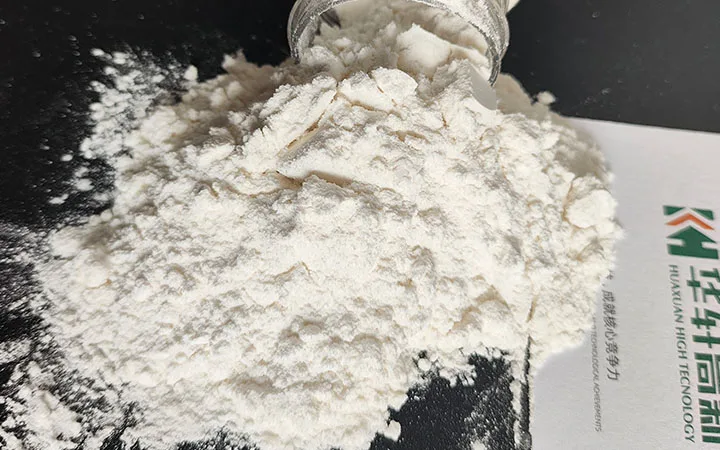

HUAXUAN technology cooperation offer a complete range of specialized high performance Cement Retarders for Oilfield applications

Features:

Types of Retarders:

1. Lignosulfonates: These organic retarders are derived from wood pulp and are among the most widely used retarders in the industry. They work by adsorbing onto the surface of cement particles, hindering their interaction with water.

2. Citric Acid and Sodium Citrate: These retarders are effective at low temperatures and are often used in combination with other retarders to achieve desired setting time.

3. Phosphates: Phosphate-based retarders are often used in high-temperature applications where other retarders may be less effective.

4. Polyacrylates: Polyacrylate-based retarders are used when specific temperature and salinity conditions must be met.

Prev: No more