Under the premise of low water consumption, the fluctuation of water addition of 10kg per square meter can increase the slump of concrete from 35mm to 200mm, but the reduction in strength can only be from 50MPa to 48MPa. When the water consumption of unilateral concrete is higher than 160kg per square meter, the increase of water consumption by 5kg may cause obvious bleeding and low viscosity of concrete with less cementitious materials.

Under the premise of the same amount of cementitious material, the water-reducing rate of concrete increases with the increase of PCE content. When the amount of cementitious material is less than 400kg per square meter or even as low as close to 300kg per square meter, a slight reduction in the PCE content will make the concrete workability worse. To ensure high slump retention effect and good working performance, compounding must be used The measures of functional components are resolved.

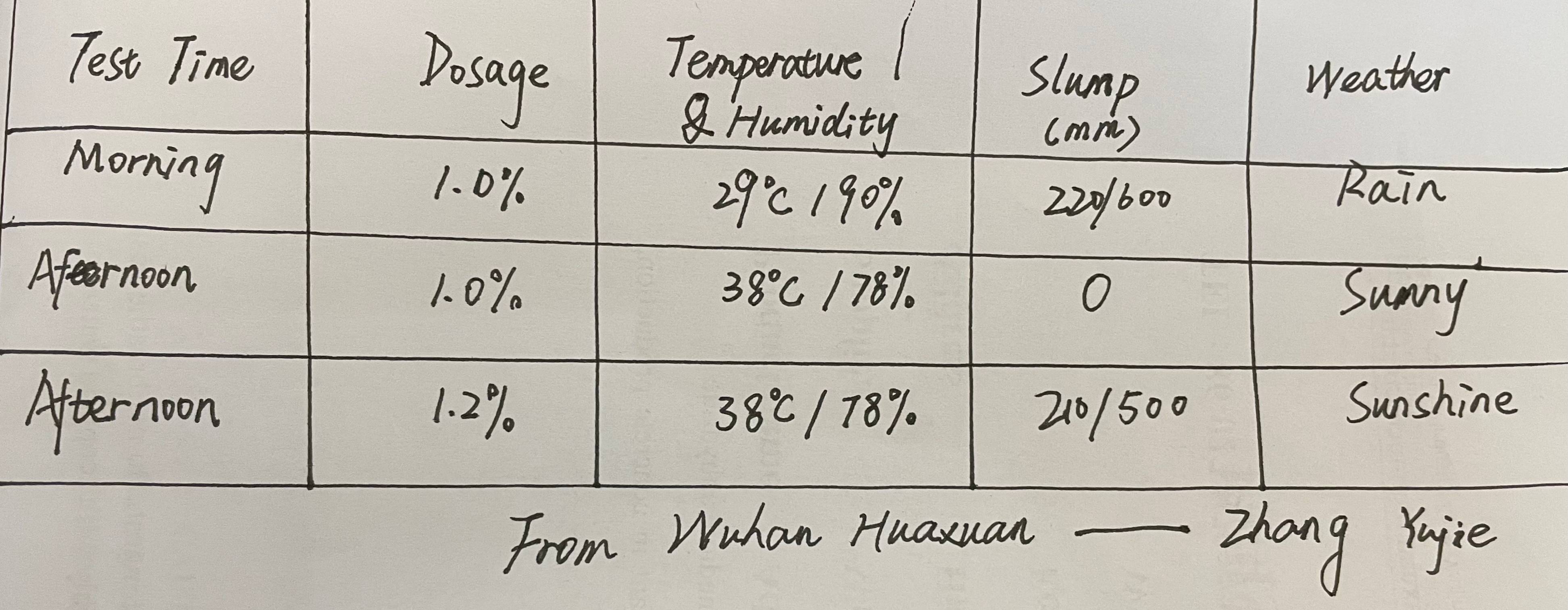

The water reduction rate of PCE in winter is slightly lower than that in summer, and the slump retention effect is higher than that in summer. Even if there are large changes in temperature and humidity in the same period, the application effect will be different.

Since the molecular structure of PCE and the mechanism of action on cement are different from those of traditional superplasticizers, the compatibility with other compounded and modified components is often different from that of traditional superplasticizers. Most of the modified components used for compounding are stable in a neutral and alkaline environment due to their own characteristics, such as Hypo, Sodium Trisparate, Dextrin, etc. Hydroxydiphosphoric acid is stable in a slightly acidic environment. If it is compounded with neutral PCE, it should be neutralized into sodium hydroxybisphosphonate first. Influence of PCE superplasticizer PH value on compound modified components

PCE produced by different manufacturers has different processes and different indoor and outdoor storage conditions. If stored under different pH conditions, the slurry fluidity and concrete strength will be different. When the pH value of the PCE stock solution is close to neutral, the pH value is 5.6-5.9, the outdoor storage for 87 days is not much different from the indoor storage stock solution, and the initial value of the cement paste is also very close to the 60-minute residual value. However, when the pH value is low, the performance of the product stored outdoors is slightly worse when the pH value is 3.0-3.4. To this end, Huaxuan technicians set up a special group discussion and conducted a comparative test in the laboratory. It was found that adding 0.13% hydrogen peroxide to the original solution can effectively prevent the solution from turning yellow (it should be colorless and transparent), and when reconstituted after a long time of storage Can be used for compounding without stirring. Storage of PCE